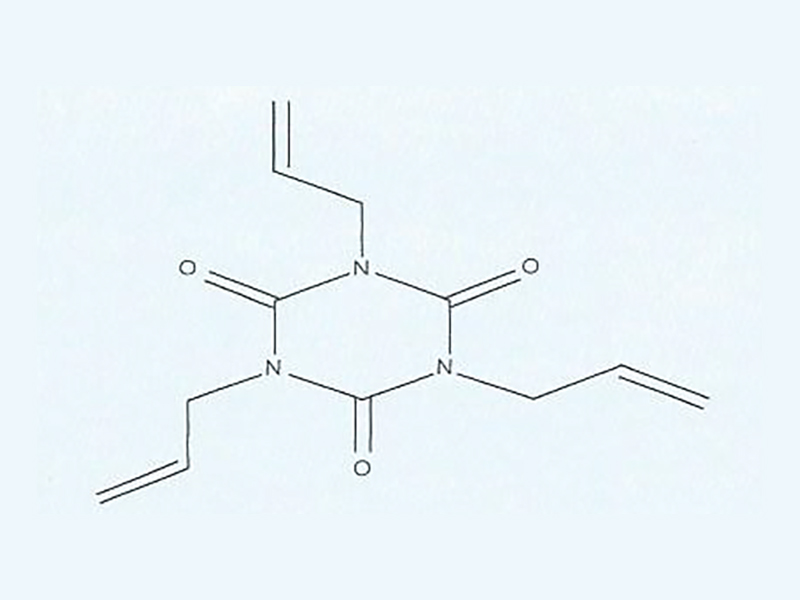

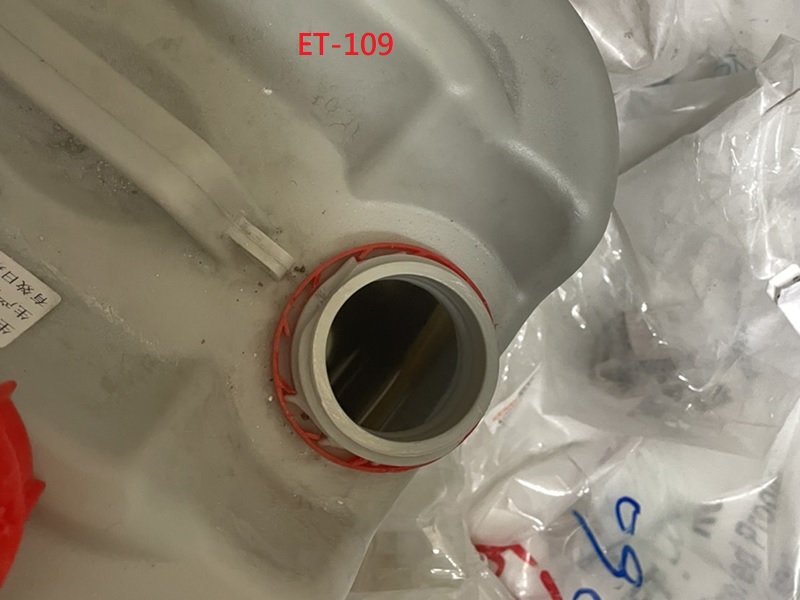

●Liquid product: ET-109 (99% TAIC)

●Powder product: ET-102 (70% TAIC, 30% white smoke)

●Appearance: light yellow liquid at room temperature (25°C), hexagonal flaky crystals when the bottom temperature (18℃) is below

Products

- Boiling point: 144°C / (3mmHg) 297℃ / (N2 760mmgHg)

- Purity: ≧ 98.6%

- Specific gravity: 1.155 (30°C)

- Moisture: ≦ 0.08%

- Melting point: 24-26℃

- Hue (clamp one-stop method): 50

- Viscosity: 85±2cps (30°C)

- Acid value: ≦ 0.3mgKOH/g

- Flash point: 355℃

- Specific heat: 0.6 (40℃)

- Refractive index: ND301.5070-1.5100

- Steam pressure: 4.5mmHg (15℃)

- Solubility: soluble in various cigarettes, acetone, various alcohols, etc., slightly soluble in lower alkane, ethylene glycol, solubility at 30°C is 0.34% .

- Toxicity: Rat oral toxicity LD50 = 666mg/kg. The homopolymer of ET-109 and the copolymer of vinyl monomers and the thermoplastic crosslinked by ET-109 will not cause any toxicity due to ET-109.

- Bridging aids: In peroxide bridging and radioactive bridging vulcanization systems, it provides rapid grafting and bridging, and the characteristics of prolonging vulcanization time make bridging more complete. TAIC is an excellent cross-linking aid for EVA foaming. TAIC is improved from TAC. Comparison of EVA peroxide crosslinking performance: TAIC> TAC> DVB> TMPTMA> DAP = EGDM.

- Modifier: Improve elasticity, toughness, oil resistance, abrasion resistance, weather resistance, corrosion resistance, yellowing resistance, adhesion, tortuous strength, tensile strength; effectively improve the compression set of synthetic resin & synthetic fiber, shorten injection molding and secondary molding time.

- Plasticizer: Improve heat resistance, can make products with different hardness and softness.

- Others: flame-retardant raw materials, thinner for coating/UV/non-volatile coating processing, medium for UV hardening (bridging) coatings.

English

English

繁體

繁體 tiếng việt

tiếng việt Español

Español 日本語

日本語 عربى

عربى Deutsche

Deutsche